One of the accidents that has most marked karting in the last thirty years is undoubtedly that of Andrea Margutti. Not many know that it was a tragic accident that took him away from us much too soon, an accident that was as tragic as it is quite a classic for karting.

One of the accidents that has most marked karting in the last thirty years is undoubtedly that of Andrea Margutti. Not many know that it was a tragic accident that took him away from us much too soon, an accident that was as tragic as it is quite a classic for karting.

One of those accidents which, as has been said several times for Romain Grosjean’s dramatic fire in Bahrain at the end of 2020, would have had very different consequences if only it had occurred today. The very young Andrea -a promise of Italian karting from the generation of Trulli and Fisichella – was fatally wounded by the collision with the seat, which caused a rupture of the aorta and the consequent, fatal internal bleeding.

From the sad stories of that day, it emerges that Andrea was not wearing a rib protector, a protective device that in 1989 was not yet widespread and that many did not wear. In the following years, the rib protector began to be part of the basic kit for the driver’s safety as, even where there were no serious accidents, it proved to be an excellent system

to prevent those small injuries to the side that often make karting painful, whether it is recreational or competitive. For years, however, many have continued to prefer a well-shaped and customized seat to this accessory, even considering it superfluous. And if indeed you happen to talk with a seat manufacturer, it would appear that there are those who say that the true prevention of trauma to the ribs is primarily implemented with a good choice of seat: this at least when it comes to trauma. from ‘wear’ and stress of the ribs, rather than related to real accidents. The development of protection systems in the meantime, as happened for example in the case of helmets and overalls, continued, until the “rib protector” was transformed into a device that protected the driver from minor traumas due to driving but also from possible harmful effects of, say, a frontal impact. With the reduction of the Mini classes and of younger and smaller drivers driving ever faster vehicles, in fact, we have begun to deal with very different accidents and cases.

In the part dedicated to the definition of the parts of the FIA Fiche it is possible to understand that it is not a simple ‘rib protector’, but a ‘Body protector’ by which it is intended to protect the area of the main vital organs. Extract from the official document “NORM FIA 8870-2018 FIA STANDARD 8870- 2018”

“BODY PROTECTION 3.1 A DEVICE WORN BY THE DRIVER TO REDUCE THE SEVERITY OF INJURIES TO THE CHEST DURING AN ACCIDENT.”

Just to give an example, think of a kart that goes off the road and collides head-on against some barrier, rather than with another kart: the force of the impact that an adult driver and a child can have on the steering wheel is very different. In the case of children, who will not have a great deal of resistance to oppose in preparation for the impact, it will be essential to passively protect that part of the chest (the sternum) that will hit the steering wheel.

When the FIA started working on the homologation of a ‘rib protector’ whose characteristics were universally valid, it started from an assumption that it should no longer be a simple rib protector, but more precisely chest and rib protection. This new protective device is designed to prevent three forms of injury: impact with flat or curved structures; impact with the steering wheel or the edge of the seat; and impact with the steering column.

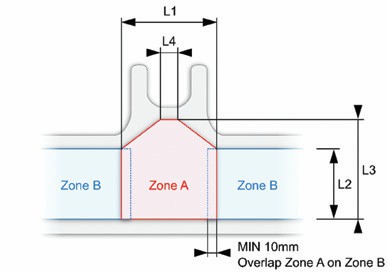

The development of the requirements was not born from the imagination of a simple designer, but is a direct derivative of the analysis of a large number of accidents (a sample of over 130) that occurred in Karting in recent years as well as the analysis of data from other sports disciplines, which have regulated similar devices. In this way, the main areas of protection of the protective device were defined, taking into account the consequences that accidents had entailed in drivers and after having found that many of the most serious injuries were due to trauma to the chest, often found hemorrhaging. The protective areas are essentially two (chest protection and rib protection) and are indicated in the figure below:

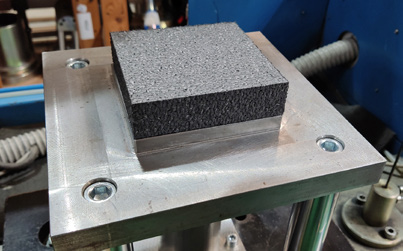

Once the product has been made, on the basis of the specifications that the FIA has established, the body protection to be homologated shall be tested by a test house approved by the FIA. The test report shall be submitted to the ASN of the country of the manufacturer, which shall apply to the FIA for the homologation. In the case of Karting body protection, the laboratory used for the tests is the very Italian NEWTON, based in Rho in the province of Milan, for twenty years an international reference for the testing of helmets (motorcycles; cars; cycling, etc.), seats and any other personal protective equipment you can think of for sports and beyond.

“We work thinking about the various ‘districts’ of the human body. Whether it is protection of sight/eyes, of the skull or of any other part of the body, with our tests we are able to reproduce most of the possible forces that act upon them as a result of the impacts that occur in situations of real use – Engineer Luca Cenedese, Director of Newton, explains – all in compliance with the criteria established by the FIA, which sends us the list of requirements. Ours is not a design role, but a test of the product that the various manufacturers carry out on the basis of the guidelines of the Federation, from which we were chosen to conduct the certification tests of the Formula 1 and WRC helmets, of the children’s helmets for kart competitions (CMR), HANS®-type devices and in 2009 for the certification tests of high-performance seats for the World Rally Championship (WRC). The new Karting Body Protection is part of this safety logic, which the FIA has embraced for years.”

Chatting with Eng. Cenedese and his collaborators at the test site where we had a close look (photo) at the machines with which the impact tests are performed, called FORCE TRANSMISSION TEST. We find out how Felipe Massa’s accident in Formula 1 (Hungarian GP 2009 practise: the CIK FIA President, at the time a Ferrari driver, is hit full on the helmet by a spring that the car in front of him had lost due to breakage); the incident marked a sort of watershed in their work as well. Accidents, in fact, can also occur in a form that on paper may not occur to anyone who designs a helmet, a back protector or any other device. Since then, for example, the helmets have been modified, first partially and then, with the subsequent homologation, introducing tests that reproduce real situations at the limits of the imponderable (literally: you now “shoot” at the helmets by means of a small cannon, an object of the size and weight of that ‘famous’ spring that struck the Brazilian driver, ed.) The primary reference for the design have become accidents, not that before they were not before but certainly to a greater and more detailed extent. We began to analyze each single accident in a much more detailed way to create design and structure guidelines for the products (or the vehicles themselves) that were aimed at reducing the risk of serious injuries. And even if initially some measures did not meet the favor of all the experts, the results have always confirmed that this is the right way.

WORTH THE MONEY

With regard to the new Kart Body Protectors wanted by the FIA, many will have wondered why the costs are much higher than those already on the market. It must be said that on the one hand, the bureaucracy behind the approval of a homologation has considerable costs for the manufacturers and, on the other hand, that satisfying the criteria established by the homologation involved research and development on materials and construction (each of the new “rib protectors” consists of 4 different parts according to specification) which started from scratch, given that what FIA requires is something completely new on the scene of our sport. Costs that can be better understood if we realize that the homologation process, as emerges from what we have examined, is the same as for a protective device such as a helmet – hence the ‘significant’ costs are indeed legitimate.

“WE WORK THINKING ABOUT THE VARIOUS ‘DISTRICTS’ OF THE HUMAN BODY. WHETHER IT IS PROTECTION OF SIGHT/EYES, OF THE SKULL OR OF ANY OTHER PART OF THE BODY, WITH OUR TESTS WE ARE ABLE TO REPRODUCE MOST OF THE POSSIBLE FORCES THAT ACT UPON THEM AS A RESULT OF THE IMPACTS THAT OCCUR IN SITUATIONS OF REAL USE.”

THE TEST

Karting Body Protection is primarily subjected to dimensional control, after which the actual test begins by means of the “Force Transmission test” machine, the same with which tests are performed on other safety devices such as motorcycle and car helmets, back protector for motorcycling or those used in motocross. A trolley (falling mass) formed by a striker (emispherycal streaker) is dropped on the “rib protector” from two different heights to exactly reproduce the two energy values required by the FIA regulations: 60 Joule for the central part (chest) and 100 Joule for the side and rear (rib). The test anvil (10 x 10 cm wide) houses a sensor (load cell) that will measure the force transmission. To simulate the presence of the “human chest” a 25mm thick polypropylene block (with characteristics known and chosen by the FIA) is used. Once the impact has occurred, if the maximum peak force recorded at any time during the impact shall not exceed 1 kN, the test is passed. The “rib protectors” used for the tests must be supplied to the laboratory in two sizes: the smallest and the largest and there must be at least 5 impact points – as established by the FIA – but they can be added at the discretion of the laboratory performing the tests, if they believe that in some specific points the product may present critical issues such as in the vicinity of rivets, air intakes or simple section reductions (rivets, bolts, buckles, adjusters or small openings for aeration).

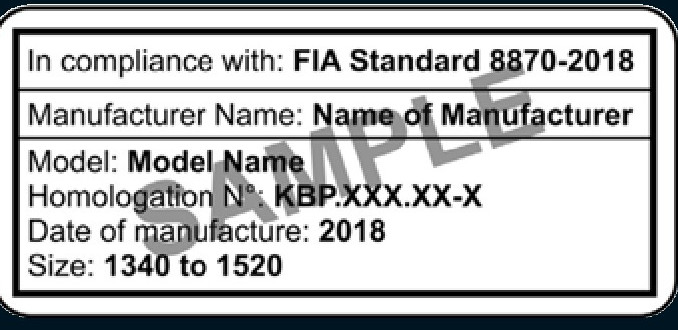

Following the test, the laboratory prepares the reports that the manufacturer sends to the Federations who will then issue homologation labels and FIA holograms to be affixed to the products that will later be put on the market.

So far, there are three manufacturers that have completed the tests required for FIA approval, but the number is expected to rise as the legislation in force this year requires the use of homologated protections – and national federations could in the future follow this line. Given that all those protective devices that comply with the values imposed by the FIA can be admitted to this type of test, each company can have its own tested, even if this is different in concept and design. It is precisely with regard to the design of the product and its conformation that the FIA reserves the right to ‘exclude’ a product from the list of those to which its approval will be issued.

Article created in collaboration with Vroom Karting Magazine.

Post time: Apr-19-2021